|

NINGBO FLUID POWER MACHINERY CO.,LTD.

|

Gold Index: 13227

You are here: home > Calibration > Calibration

Product (210)

- Hydraulic Tube Fittings & Hose Fittings (126)

- Machining Parts (64)

-

Stampings

(9)

- Alumina Stamping (1)

- Steel Stampings (8)

- Casting & Forging Parts (9)

-

Valves & Pump Parts

(1)

- Valves Parts (1)

- Others (1)

Special Groups (1)

- BOLT (1)

Equipment (13)

Why Choose Us (5)

Links & Download (6)

Certificates (1)

Calibration (1)

Quality Management (4)

Factory Glance (5)

Applications (11)

Reference Letter (4)

Blog (19)

Credit Report

Products Index

Calibration

Calibration

1. What Is the Importance of Calibration?

The importance of calibration is that, it is used to measure accuracy and compares the measuring instrument that has a standard to determine the possible errors in a specific scale. It is also used for the process of manufacturing less possible mistakes and errors that can be made. The process of measuring apparatus, is also used to lower the cost to manufacture.

The importance of calibration is that, it is used to measure accuracy and compares the measuring instrument that has a standard to determine the possible errors in a specific scale. It is also used for the process of manufacturing less possible mistakes and errors that can be made. The process of measuring apparatus, is also used to lower the cost to manufacture.

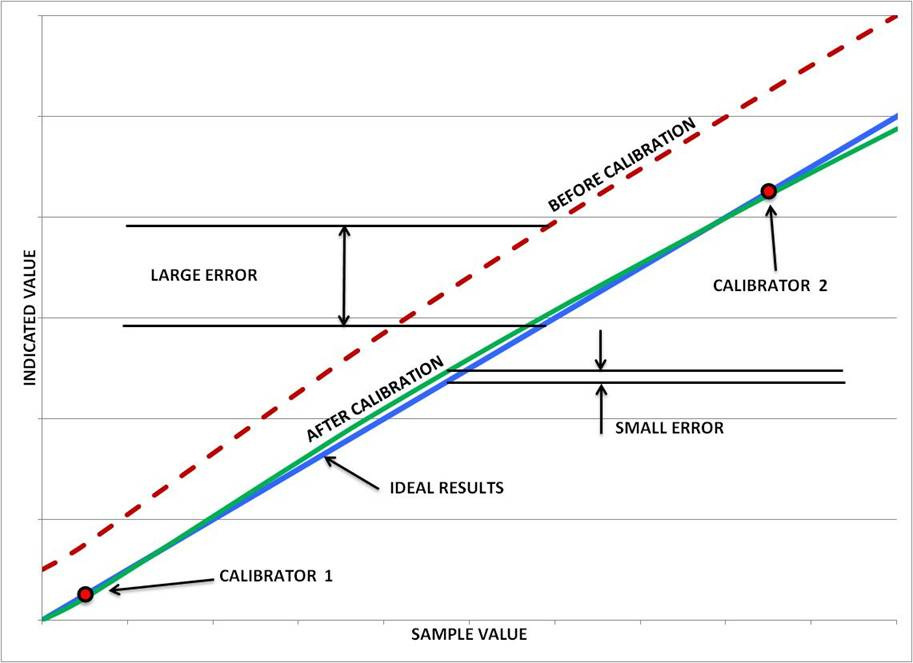

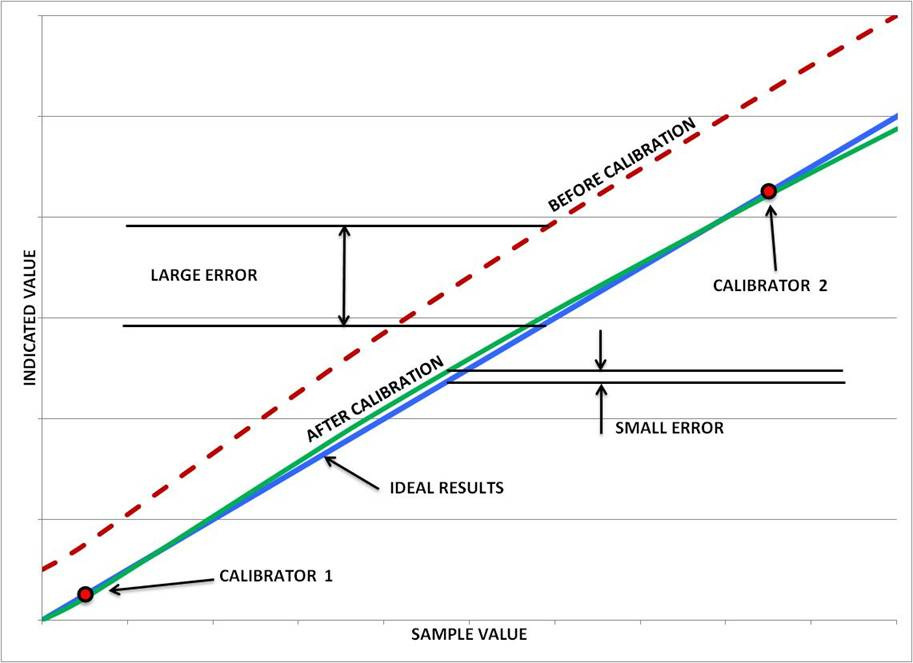

Ideally a product would produce test results that exactly match the sample value, with no error at any point within the calibrated range. This line has been labeled "Ideal Results". However, without calibration, an actual product may produce test results different from the sample value, with a potentially large error.

2. How NBF make the calibration?

A. TESTED / VERTIFIED by the official(designated) THIRD PARTY, including the material test, salt spraying test, etc, in the process of manufacturing OR before shipment;

B. MACHINES/TOOLS have to be confirmed without any error. maintenance upkeep-er will come to our factory twice a year and a CERTIFICATE will be offered per time.